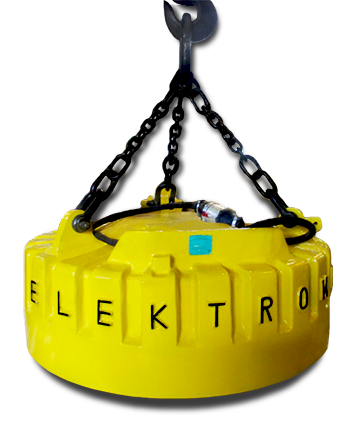

ELEKTROMAG DEVICES P LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ELEKTROMAG DEVICES P LTD.

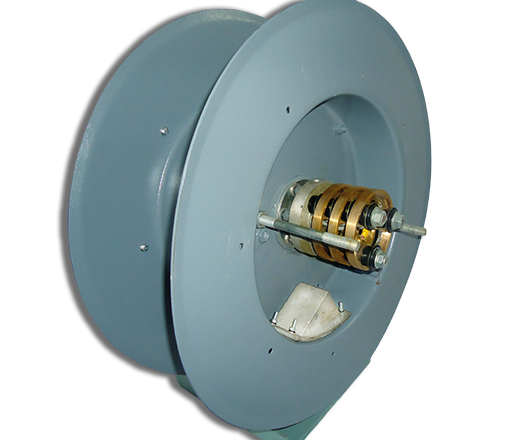

Spring Operated Cable Drum

Powered by clock type springs and rotating on sealed for life bearings. ELEKTROMAG drum offer a convenient, cost effective means of supplying power to moving machinery. With heavy duty, one piece drum halves and a painted finish the reels are suitable for operation in arduous conditions.

Mechanical Construction

General Construction

By using one piece drum halves made from heavy gauge steel. ELEKTROMAG has designed a range of drum that is both strong and waterproof whilst employing the minimum of components. The drum revolves on a pair of "sealed for life" ball races resulting in the complete reel being maintenance free.

Springs

ELEKTROMAG springs have been proved in service for many year and are manufactured from the highest quality materials. They are of the “clock spring” or spiral wound type and by using the springs singly or assembled in series or in parallel, a wide range of performance characteristics is obtained from the standard range.

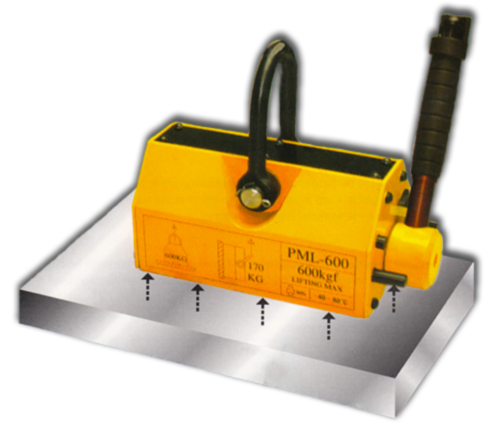

Sprocket Cable Reeling Drum

These types of cable reeling drums are used to avoid tension on the cable. Hence recommended for lifting magnets / or any other vertical application on crane. However a drive mechanism is required to drive the reeling drum which is not required in case of spring operated or mortised reeling drum.

Following information is required send offer

Of the distance travelled by crane hook (up or down) in one rotation of the rope drum.

The shaft diameter of the rope drum where the sprocket for driving the cable reeling drum hill be time.

Rope Drum diameter .

No. of falls of Ropes.

T.C. Series Stall Torque Motorised Cable Reels

The reel compartment is constructed from one piece drum halves manufactured in heavy gauge steel to produce range of reels that are both strong and waterproof whilst employing the minimum of components. The drum revolves on a pair of “sealed for life” maintenance-free ball races, is mounted on a heavy fabricated steel base frame and is driven via an enclosed drive by a squirrel cage geared torque motor complete with brake.

The sliprings are each complete with a double leg brush-holder providing 2 brushes per ring to cater for adequate capacity to cater for starting current peaks and are designed for up to 600V AC operating voltage to comply with the relevant IS, BS, VDE, CSA AND NEMA specifications regarding minimum air gaps and creepage distances.

The slipring compartment and motor are designed and built to IP55 protection.

The wide reel compartment enables greater cable lengths to be handled than would normally be possible whilst at the same time keeping the overall diameter of the reel to a minimum.

This enables an inexpensive motor drive system to be utilized, resulting in a compact reeling solution for horizontal recovery applications at speeds of up to 40/min. and accelerations of 0.2m/sec2 with the reel mounted 1.5m above ground level.

The reel is suitable for continuous energisation eliminating the need for any associated control system

Torque Regulator Powered Cable Reels

ELEKTROMAG have available a complete range of motor driven torque regulator reels, The reels shown in this catalogue are direct reeling units where the cable compartment is mounted directly on the torque regulator For those applications where the length and weight of the cable is in excess of the design capability of the direct reeling units, we have the indirectly driven torque regulator reels. With these reels the torque regulator unit powers the reel compartment through a suitably selected transmission.

ELEKTROMAG have produced in the TR range a reliable, low cost solution to the problems of reeling long lengths of cable at the high duty cycle rates demanded by today’s heavy industry. ELEKTROMAG range is now available for the complete range of cables for lengths from 3O to 1OOO meters, for voltages upto 11OOO volts.

Having decided to use a TR motor driven reel to power your particular moving machine, you will have selected a system that is easily installed, has an absolute minimum maintenance requirement and is virtually unaffected by extremes of temperature and environment. TR reels in their hundreds are now operating in steelworks, ship and ore stockyards, mines, factories etc., in most countries in the world.

ADVANTAGES

Uses standard AC or DC motor as prime mover.

Design reduces substantially tensions in reeled cable as against other forms of drive.

Lubricated for life gearbox.

Range of drive units to suit various sizes and lengths of cable to be reeled.

Reduced overall size as compared with conventional motor.

Brake is a function of the design.

No chain drives, no maintenance.

Can be used in hazardous areas and shipboard.

WORKING

The power unit drives the reel through an irreversible worrn and wheel transmission which is totally enclosed and lubricated for life. The reduction ratio of the gearbox is fixed and rotational speed of the output spindle is selected by fitting the appropriate speed motor unit. Since the motor mounts are designed to accept universally available stock motors, variations in reeling speeds are easily obtained. In all cases, rotational speed of output spindle is arranged to be in excess of that required for cable reeling which ensures correct cable retrieval under all operating conditions. The energy dissipating capability of the torque regulator unit is greater than the energy permissible through the gearbox thus ensuring adequate safety margins are applied to torque regulator unit. The torque regulator employs an advanced design friction principle and the unit incorporates a unique arrangement to give stable performance during all operating conditions. A very large area of friction lining in relation to the energy dissipated ensures an extremely long period between lining replacement. Special consideration has been given to lining renewal, if due to a particularly high duty cycle, this ultimately becomes necessary and the complete replacement of the linings can be accomplished by an unskilled person in less than 5O minutes. The heat dissipating arrangements employ a thermo syphon principle when the reel is in its stalled condition and self-induced air flow when the reel is revolving.

The cable compartment is directly mounted on the torque regulator unit which is easily adjustable in output to suit the various combinations of cable size and length to be reeled. The speed differentials encountered during reeling in and out are accommodated by the torque regulator using the friction drive as a slipping interface.

When engineering torque motor or fluid coupling reels it is very easily established that the inertia of the torque motor rotor or fluid coupling casings coupled with the effect of back driving relatively high reduction ratios produce massive increase in cable tensions.

For this reason the slipping interface of the torque regulator has been positioned on the outboard shaft of the transmission thus isolating the reel from referred inertia effects. The irreversibility of the worm and wheel transmission and the stable torque characteristics of the torque regulator permit successful cable reeling on the basis of energising the motor for recovery only. The benefits of energising the reel motor for cable recovery solely are not only increased friction lining life and great extended intervals between torque correction but of course massive savings in energy consumption.

N.B. For the fixed torque reels, owing to the relatively low torque output of these units, these can be energised continuously without any adverse effect on the friction lining life, thus eliminating the need for any control system.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.